A look back at the startup’s ESA BIC Poland journey — from initial concept to flight-ready 3D printing technology.

Orbital Matter has successfully completed its incubation at ESA BIC Poland, marking an important step in their mission to enable construction directly in space using 3D printing. Their goal? To design and fly a printer that works in vacuum and microgravity, making it possible to build large structures directly in orbit.

From Concept to Flight Readiness

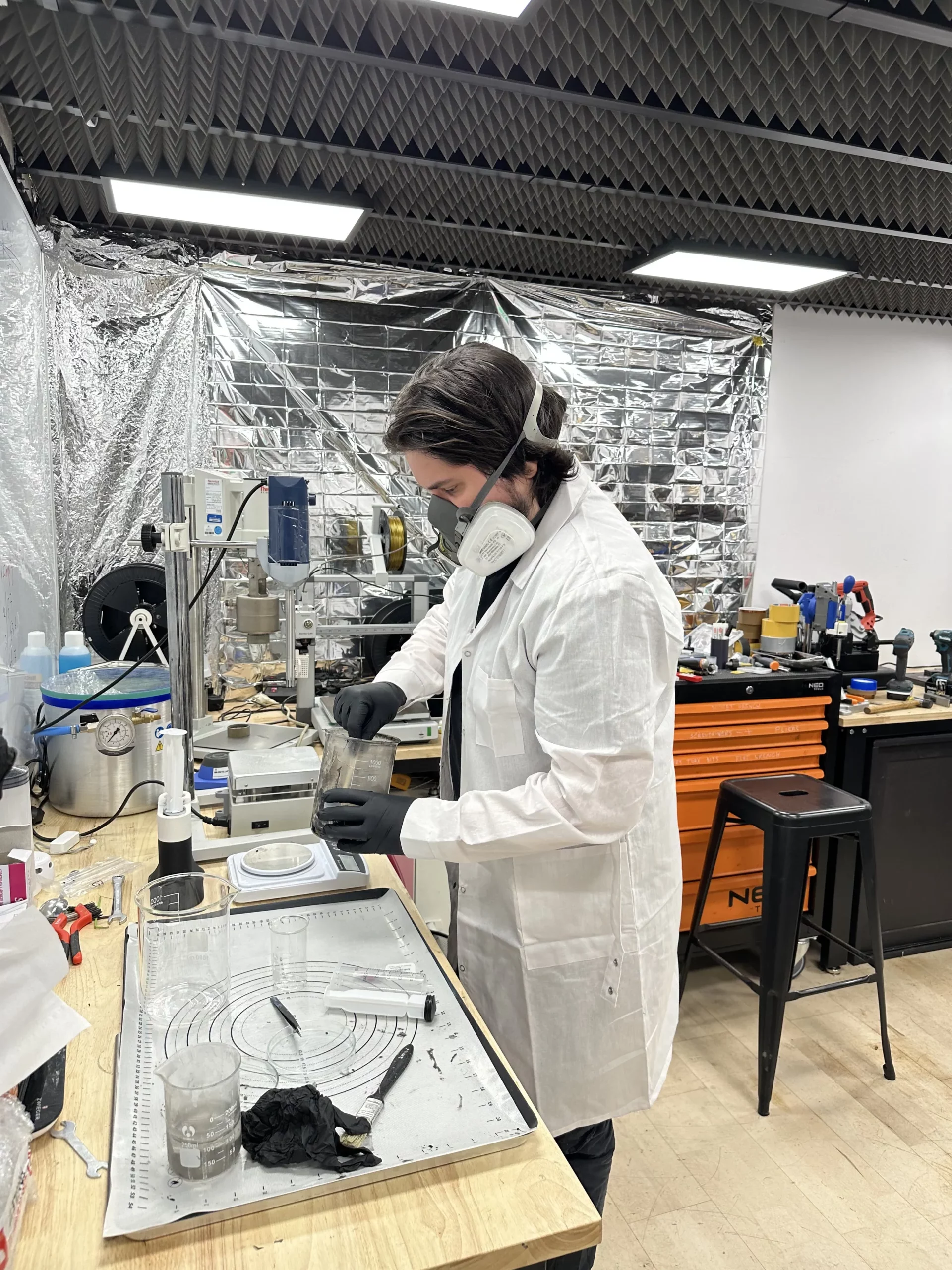

When entering the ESA BIC Poland program, Orbital Matter had already proven the core principles of their technology. Over the incubation, they advanced it significantly — designing a space-ready printer, building a physical prototype, running testing campaigns, and filing an IP application to protect their innovation.

They even attempted their first satellite launch, showing how far they’ve come in turning an ambitious concept into reality.

Securing the Foundation for Growth

The startup secured a remarkable €1.1 million pre-seed round led by Sunfish Partners — a significant milestone for a young company operating in the demanding space sector. This early investment gave Orbital Matter the momentum to accelerate development, attract talent, and strengthen its position in the space innovation landscape.

Entering the Market with Key Industry Players

Orbital Matter made significant business development progress during the incubation. They signed a Memorandum of Understanding with Thales Alenia Space, followed by a paid pilot agreement for their upcoming demonstration mission.

They also built close relationships with major industry players such as Axiom Space and OHB — collaborating on use cases and applying for joint opportunities across various programs.

Beyond those commercial efforts, the startup also benefited from tailored legal consultations through the ESA BIC network, particularly around intellectual property strategy — a key element for any space-tech innovator.

What’s Next?

As the incubation draws to a close, Orbital Matter is shifting gears toward the next stage of growth. On the technical front, the team is refining its flight-model 3D printer, aiming to showcase its capabilities in deploying systems directly in orbit — a breakthrough step for in-space manufacturing.

At the same time, they are actively building consortia and drafting proposals for upcoming ESA calls, with a particular focus on the ARTES programme. Their growing visibility in the space ecosystem is opening new doors to collaborations and strategic projects.

After building a strong base during the incubation, Orbital Matter is now getting ready for a new stage of growth — moving closer to real use of their technology in space.